Structure design based on the product complexity and the manufacturing process.

Helix processing includes R-direction, L- direction, Double-direction, boat-bottom shape cutting, wave shape cutting, etc. Helical cutting angle

can reach acute angle.

Mold processing is under the central control program to ensure the product quality. Mold tolerance, based on customer requirement, is normally is between – 0.01mm and 0.01mm. However a tolerance within - 0.0035mm ~ + 0.0050mm is achievable.

Finishing quality of the mold can reach Ra 0.6 through cutting. The surface smoothness can be enhanced by further processing. (Ra 0.04 is possible.).

The life span of the mold can be elongated up to 10 years because of the material used in production along with our demolding technique and heat procession. Our mold products can withstand multiple vulcanization and pressurization without being deformed or damaged easily.

To expedite the process of product development and improve the quality of products, when lacking the specifications of the sample item, we can restore the original data with reverse engineering tools, which can also be used in comprehnesive quality inspection on finished products and

thus increase the quality stability.

With our database, we can share our experience with customers and provide product related advice to lower the possibility of problems occurring after the development. Moreover, we can put more insights into the discussion when developing a product and further improve the product quality and manufacturing technique.

Commissioned items will be measured by 2D CMM or 3D scanner, and drafted with computer programs. Product information will be encrypted and filed into respective account for the purpose of quality control and customer service.

Based on the sample or end product drawing, we will evaluate the possibility of developing the product.

Quote under the complexity of the mold structure.

After the order is placed, we will arrange the processing and evaluate the delivery date.

After the specifications and the related information are confirmed, we will begin designing the mold and programming.

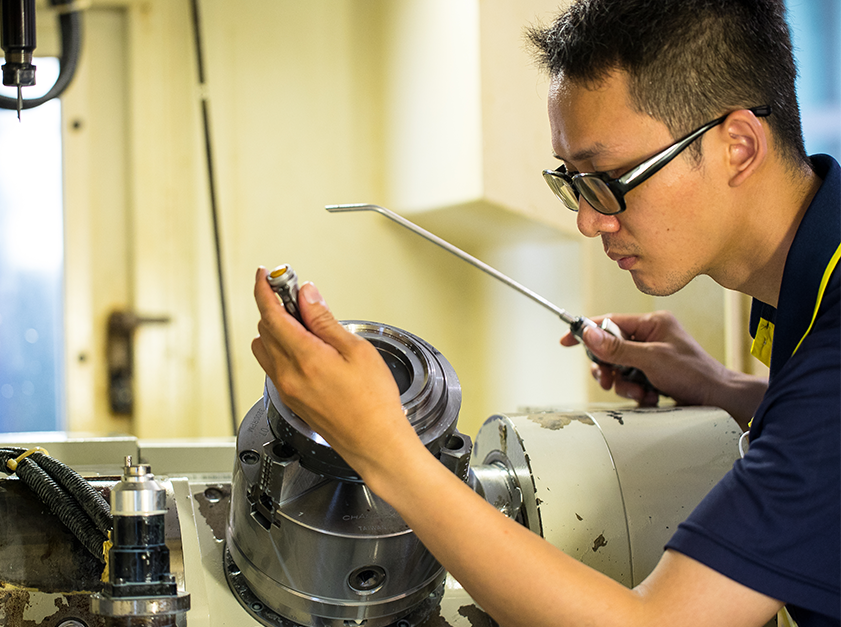

Arrange the mold for processing.

When finished, the mold will be tested with the metal rings and rubber offered by the customers

When the sample is done, we will provide the sample and specifications for you to check. If there is no further question, we will send out the finishing product.

The mold will be covered in rust-preventative oil, packaged, and delivered to the customer.

VIEW MORE![]()