A:The hardness of the mold ranges from HRC48 to HRC52.

A:The basic material is high carbon steel. Customized material is negotiable.

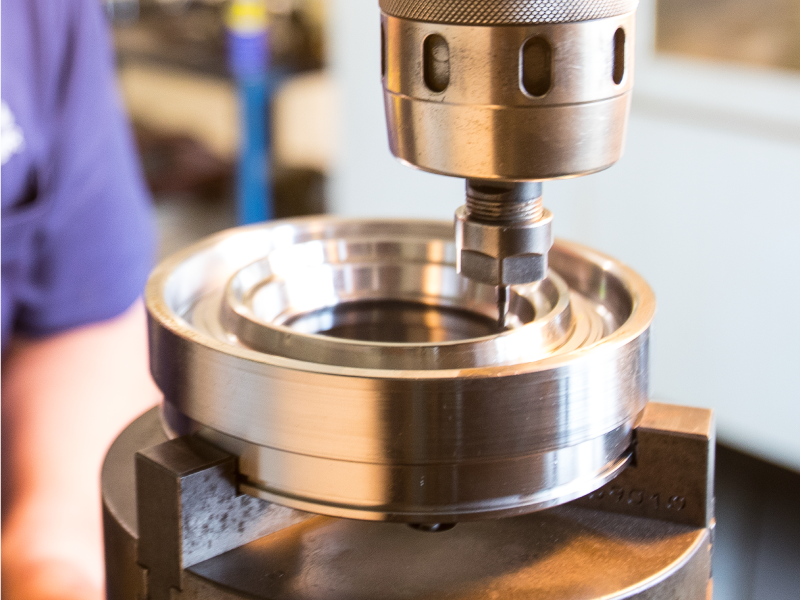

A:After the specifications are confirmed, we will begin the manufacturing process. The mold will go through rough turning, after which it will be processed with heat treatment, and then finish turning. After the specifications are rechecked for tolerance, the mold is ready for delivery.

A:When the rubber material used is corrosive, we suggest using electroplated layer to improve the durability.

A:If the mold is in round shape, the range of the outer diameter can be from 70mm to 600mm, which means the outer diameter of the end product is achievable within the range from 0 mm~522 mm. Besides, we offer mold plates as an alternative. Molds of size other than what is mentioned above are negotiable.

A:Please make sure that the measurements of the end product are correct, and provide the shrinkage rate and information of the machined used.

A:Yes, we offer repair service subject to the extent of the damage. (E.g. the mold is damaged in vulcanization.)

VIEW MORE![]()